Description

Boart Longyear has combined proven technology from its most popular surface coring drill rigs to create the powerful LF™160. When paired with the FL262 FREEDOM™ Loader, the LF160 combination is ideal for contractors who want to target sophisticated surface drilling exploration contracts that stipulate some of the highest safety standards, without compromising on productivity.

TILTING TOP HEAD DRIVE

The tilting top drive head simplifies rod handling with built-in tools and functionality such as the rod clamp, the spring-loaded floating spindle, and the tilting function of the head.

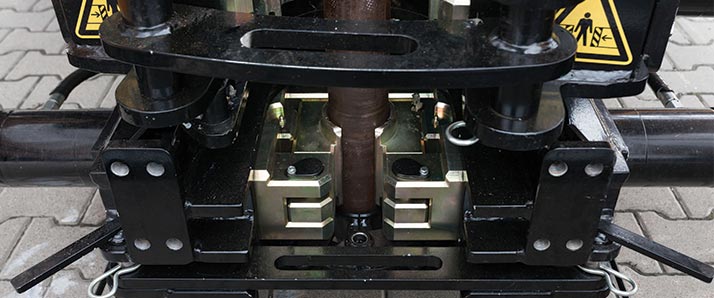

FOOT CLAMPING AND BREAKING DEVICE

The foot clamp and breaking device is four tools built into one: the lower rod clamp, upper rod clamp, a rod making alignment device, and a rod centralizer.

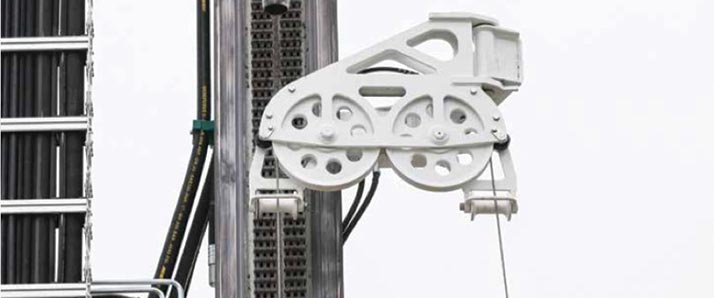

VISIBLE WIRELINE

Wireline winch is located in front of the mast, inside the rotation barrier for improved visibility. The driller can monitor the wireline spooling from the control panel, avoiding tangling of wire rope typically experienced while lowering overshot.

THE FREEDOM™ LOADER (FL262)

Introducing the FL262, the first product in Boart Longyear’s emerging FREEDOM™ rod loaders, handlers, and presenters. Our cutting-edge range has been engineered with drillers’ safety and productivity front-of-mind.

FEATURES

- TILTING TOP DRIVE HEAD

The forward tilting head design simplifies the rod handling process and reduces the need for operation intervention and maintenance. - CLAMPING AND BREAKING DEVICE

A hydraulic breaking device means no wrench under power. Rod alignment device and centralizer included. - CE CERTIFIED

The LF™160 is CE certified according to the latest safety standards. - VISUAL WIRELINE

The wireline winch and sheaves are located in the front of the mast, inside the rotation barrier, for improved visibility. - DEPTH CAPACITY

With up to 1,800 meters of NQ™ capability, the LF160 can cover the majority of diamond coring needs. - ENVIRONMENTALLY CONSCIOUS TIER 3 OR 4 ENGINE

Offered with either a Tier 3 or 4 final engine to comply with emissions requirements in every country. - VERSATILITY OF CARRIERS

The LF160 can be ordered in either a crawler or truck mount configuration. The truck mounting is compatible with international 6×4 and Mercedes 8×8 or 6×6 trucks.

| Specification | Metric | U.S. |

| Diamond Core NQ™ / NRQ™ / NRQ™ V-Wall™ | 1,800 m | 5,900 ft |

| Max Pull Back Force | 170 kN | 38,200 lbf |

| Maximum Rod Pull Length | 6m | 20 ft |

| Engine (option), Tier 4 Final | Cummins QSB 6.7 Diesel Engine | |

| Maximum Power @ 2300 RPM | 194 kW | 264 HP |

| Engine (option), High Altitude, Tier 3 | DEUTZ TCD 2013 L06 4V Diesel Engine | |

| Maximum Power @ 2000 RPM | 227 kW | 304 HP |

DOWNLOAD COMPLETE CATALOG